June 09, 2022 - By Promostyl

3D WEAVER - THE REVOLUTIONARY 3D WEAVING

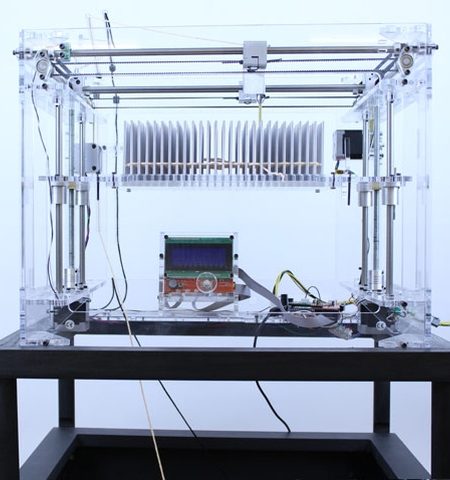

Royal College of Art graduate Oluwaseyi Sosanya designed a 3D weaving loom for his degree project The Structure of Protection. To demonstrate and illustrate the capabilities of this innovative weaving, Sosanya wove a shoe sole made of a continuous thread, in collaboration with shoe designers Lixian Teng and Tomiwa Adeosun, presented at the institution's annual graduation exhibition.

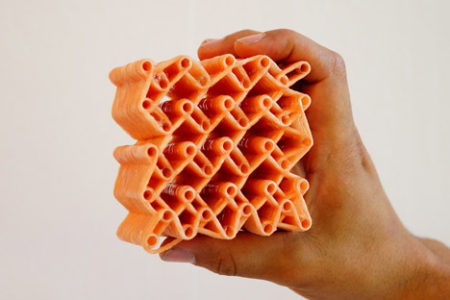

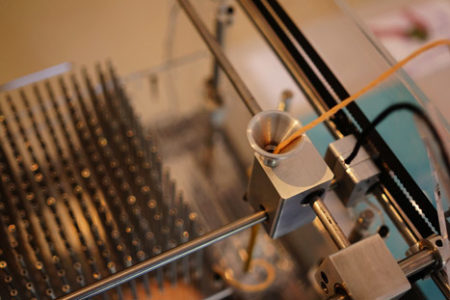

This machine, inspired by traditional weaving and knitting machines, weaves interconnected layers of straight warp yarns and interwoven weft patterns at different heights, creating a third dimension. This 3D weaver can twine anything, from wool to cotton, into a three-dimensional structure that is then dipped in silicone to retain its structural properties. The machine works by passing thread through a nozzle that wraps around the warp threads. Once the object is finished, the bottom of the printer slides out and ejects the object from the tubes.

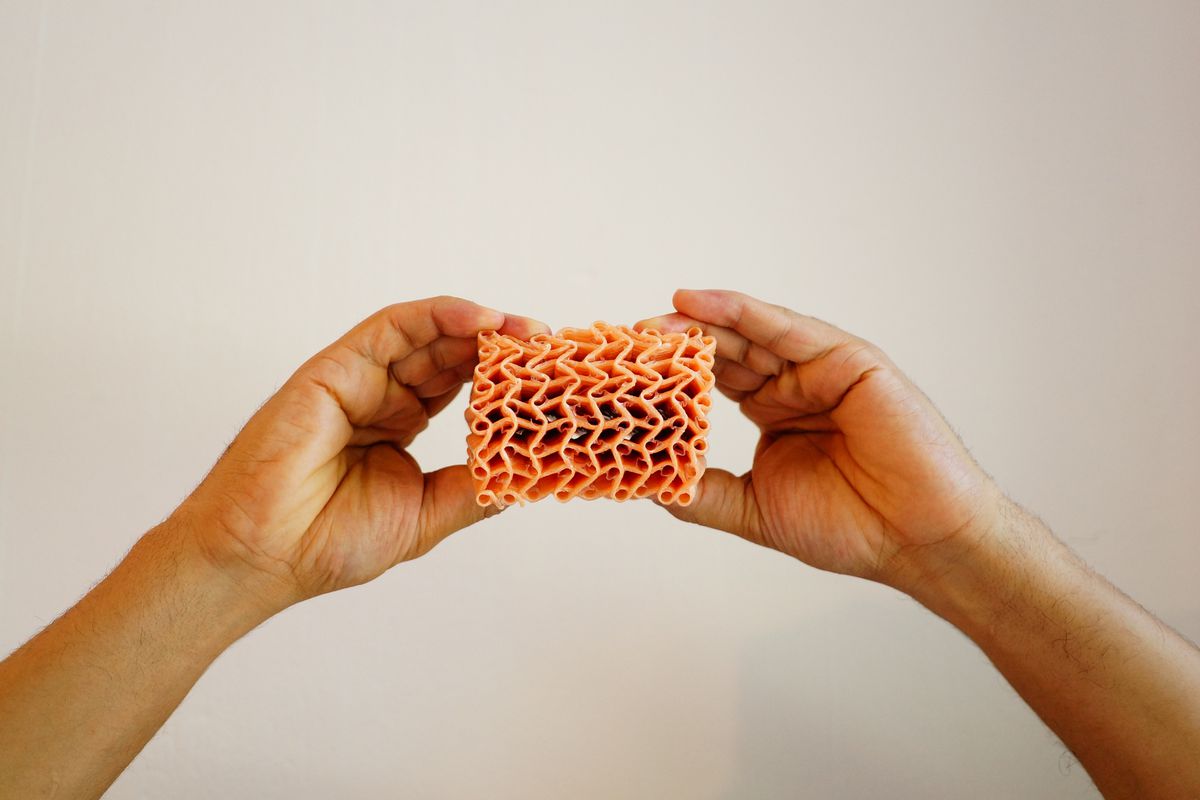

With this system it's possible to pre-program the density in different places and levels of the created piece, allowing us to have a piece more adapted to our needs. The objects created by this process are both flexible and solid but also with a 90% memory of shape.

3D Weaver could be used to create protective sportswear, bulletproof vests, medical implants and even architecture. However, at its current scale it is more appropriate to the design of shock-absorbing sportswear than to construction.